Thermoforming Tooling

In the realm of plastic manufacturing, one of the most widely used processes is thermoforming. This method, which involves heating a plastic sheet and shaping it over a mold, has transformed industries by offering a cost-effective, versatile, and efficient way to produce a variety of plastic products. At the heart of this process lies the concept of Thermoforming Tooling, a critical element in ensuring the accuracy, efficiency, and quality of thermoformed products. Whether you’re producing packaging, automotive parts, or consumer goods, the right thermoforming tooling can make a significant difference in the success of your production.

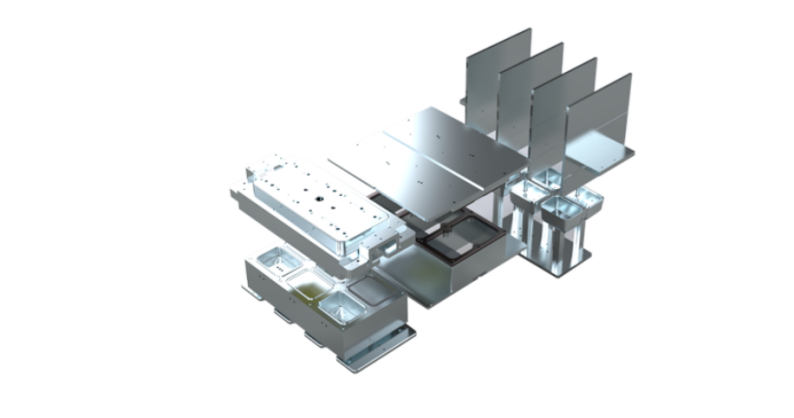

What is Thermoforming Tooling?

Thermoforming tooling refers to the set of tools and equipment used to shape plastic sheets into the desired form. These tools typically include molds, trimming tools, and cutting devices. The term “tooling” encompasses all the necessary components to create the final product, from the initial heating phase to the final trimming and finishing.

Components of Thermoforming Tooling

Thermoforming tooling can be divided into several key components, each of which plays a vital role in ensuring the successful production of thermoformed products:

Molds: The mold is the most essential part of thermoforming tooling. It is the component over which the heated plastic sheet is shaped. Molds can be made from a variety of materials, including aluminum, steel, and even composite materials, depending on factors like the production volume, material type, and desired level of detail in the final product. There are two main types of molds:

Male Molds: These molds have a protruding shape and are typically used for creating products such as trays, containers, and packaging items.

Female Molds: These molds have a recessed shape that the plastic sheet is drawn into, and they are typically used for creating hollow items like cups, bowls, and certain packaging applications.

Trimming Tools: Once the plastic has cooled and solidified in the mold, excess material must be removed.

Trimming tools are used to cut away the edges of the formed plastic sheet to give it a clean finish. These tools can be automatic or manual, depending on the complexity of the product and the production requirements.

Vacuum and Pressure Systems: In some thermoforming processes, vacuum or pressure systems are used to pull or push the heated plastic sheet into the mold. These systems are essential for ensuring that the plastic material fills the entire mold cavity, eliminating air pockets and ensuring uniform thickness.

Cooling Systems: After the plastic is formed, it needs to cool quickly to retain its shape. Cooling systems integrated into the tooling are used to regulate the temperature of the mold and the plastic. This is often achieved through channels in the mold that circulate water or air to cool the material evenly.

Materials Used in Thermoforming Tooling

The materials used in thermoforming tooling are crucial to the success of the process. The selection of materials affects the mold’s durability, heat conductivity, and cost-efficiency. Some common materials used in thermoforming tooling include:

Aluminum: Aluminum is one of the most popular materials for thermoforming molds due to its lightweight nature, excellent heat conductivity, and relative affordability. Aluminum molds are ideal for short to medium production runs and are often used for products that require high precision.

Steel: Steel is often used for high-volume production runs and for applications requiring high durability. Steel molds are more resistant to wear and can withstand higher temperatures, making them ideal for industries such as automotive and heavy-duty packaging.

Importance of Thermoforming Tooling Design

The design of thermoforming tooling is critical to achieving high-quality products and ensuring efficient production. The precision of the tooling design influences the accuracy of the formed plastic, the smoothness of the finished product, and the overall cost-effectiveness of the manufacturing process.

Precision and Accuracy: The tooling design must match the product specifications with great precision to ensure that the final product meets quality standards. Small deviations in the tooling can result in defects like warping, uneven thickness, or improper fit.

Ease of Removal: The tooling design must ensure that the formed product can be easily removed from the mold once it has cooled. A well-designed mold will minimize the risk of the product sticking to the mold or getting damaged during the removal process.

Ventilation: Proper ventilation in the tooling is essential to avoid air pockets and ensure smooth molding. Without sufficient venting, the thermoformed product may have defects such as bubbles or inconsistencies in thickness.

Applications of Thermoforming Tooling

Packaging: Thermoforming tooling is extensively used in the packaging industry, especially for producing blister packs, trays, and clamshell packaging. The versatility of thermoforming allows for cost-effective production of packaging for consumer goods, food, and medical products.

Automotive: In the automotive industry, thermoforming tooling is used to create parts such as dashboards, trim components, and interior panels. These parts often require precision molding to fit complex shapes and meet stringent durability standards.

Medical: Thermoforming is crucial in the medical industry for creating sterile packaging, trays for medical instruments, and other medical devices. High precision and quality are essential in this field, and tooling must meet stringent regulatory requirements.

Consumer Goods: Many everyday consumer goods, such as toys, containers, and electronics housings, are produced using thermoforming. Tooling is often custom-designed to meet the specific shape, size, and durability requirements of these products.

Conclusion

In conclusion, Thermoforming Tooling plays a pivotal role in the plastic manufacturing process. From molds to trimming tools and heating systems, the proper tooling is essential for creating high-quality, efficient, and cost-effective thermoformed products. The right design, material choice, and maintenance of thermoforming tooling can significantly impact the speed, cost, and overall success of the production process. Whether you’re in packaging, automotive, medical, or consumer goods, understanding and investing in the best thermoforming tooling will help ensure the quality and consistency of your products.